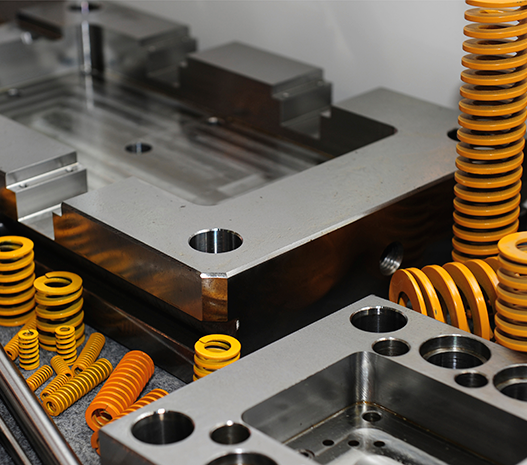

After rapid prototyping proves your design and we’ve clarified all requirements affecting the design of the mold, we’ve reached the next phase in the manufacture of your plastic part. We’re ready to have your injection mold built. So let’s talk a bit about injection mold design.

Some of the major features that need to be considered when choosing the right injection mold would be:

- The type of runner system. A few examples of this would be a hot runner system, insulated runner or a cold sprue.

- Type of gating required. (Direct sprue, edge, fan and tunnel gates to name a few.)

- The presence of holes or undercuts on the side edges of the part to be molded would require the use of cams in the mold.

- The manner in which the molded part is released. This would include type of ejection used for the molded parts and means of separation.

Some of the types of injection molds are:

- Standard molds or two-plated molds.

- Split-cavity molds or split-follower molds.

- Stripper plate molds.

- Three-plate molds.

- Stack molds

- Hot-runner molds.

We use ejector pins and sleeves most often to eject the molded parts. Some part designs require the use of blades, lifters or stripper plates.

The ejector pins and sleeves also serve to help vent the cavity. This gives air and gasses a place to go when filling the mold cavity with plastic. With the advent of EDM machining, venting has become much more important. A poorly vented cavity can cause a poorly manufactured part. Over time, this could lead to deposits building up in the mold, burning (the diesel effect), and corrosion.

When looking to make molds that last, you have to look for materials that have a high resistance to wear and corrosion. You also want to choose materials that will offer high dimensional stability over the life of your product.

Tool steels are the better material choice for building an injection mold. The material selected for the mold should also be carefully made based on the resins we’re processing. When we get to this stage with you, we’ll talk at length to be sure we pick the right steel for your mold.

Choosing the right injection molding is crucial to the successful manufacture of your plastic part. Next time we’ll discuss the specifications of the various mold classifications.

Until then,

Rollin

PS Reference for this post: Lindner, E. and Unger, P. Injection Molds: 108 Proven Designs 2nd ed. Hanser Publishers