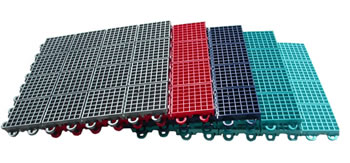

If the project calls for several different sized parts, we can usually mold all of them here in our facility. This not only helps us keep colors consistent, but it lowers costs. That’s because we can buy material at higher volume discounts and plan the final assembly more efficiently.

If the project calls for several different sized parts, we can usually mold all of them here in our facility. This not only helps us keep colors consistent, but it lowers costs. That’s because we can buy material at higher volume discounts and plan the final assembly more efficiently.

Our 17 injection molding machines range from 33 to 528 Tons. Several of these are now hybrid and electric machines, which help us run clean, repeatable, and energy efficient. For example, our Roboshot 330 Ton reduces energy consumption by 50% to 80% with repeatable, precise cycles. See our complete list of machines below.

Our molding area is equipped with dryers, chillers, granulators, core pull units, mold temperature control units, automatic hopper loading, and assorted coloring equipment.

We can finish your part in our shop with hot stamping, assembly, jigs for specialized drilling and milling, ultra-sonic welding, and packaging. We can also dress up your parts by having them metalized, painted, or decorated with screen or pad printing.

Sub-assembly, either in-line or post molding, can often be incorporated into our manufacturing process. Our engineers analyze the process and see where some sub-assembly may help you save time and money.

.

Our 17 Injection Molding Machines

- 1-528 Ton 75 oz. Haitian (Hybrid)

- 1-528 Ton 65 oz. Haitian (Hybrid)

- 1-500 Ton 70 oz. Cincinnati (Classic)

- 1-385 Ton 28 oz. Cincinnati (Electric)

- 1-360 Ton 28 oz. Haitian (Hybrid)

- 1-330 Ton 28 oz. Cincinnati (Electric)

- 1-300 Ton 20 oz. Cincinnati

- 1-250 Ton 13 oz. Cincinnati

- 1-220 Ton 20 oz. Cincinnati

- 1-220 Ton 8 oz. Cincinnati

- 1-165 Ton 13 oz. Cincinnati

- 1-165 Ton 11 oz. Cincinnati

- 1-135 Ton 9 oz. Haitian (Hybrid)

- 1-110 Ton 7 oz. Cincinnati

- 1-110 Ton 5 oz. Cincinnati

- 1- 50 Ton 1 oz. Cincinnati (Electric)

- 1- 33 Ton 1 oz. Cincinnati

Call us at 315.841.4101 or click here to get a quote or ask us a question.

| << Color Matching | Assembly & Packaging >> |